Unleash the Power of Smart, and Integrated Manufacturing with New age MES System - EzeMES

EzeMES

Power of Smart, Integrated Manufacturing with New age MES System - EzeMES

EzeMES unlocks the combined potential of Machines, People and Processes to streamline productivity on the factory floor, resulting in increased productivity and reduced wastage. EzeMES offers the tools to plan, monitor, control, and optimize manufacturing operations.

EzeMES MES is an advanced manufacturing execution system designed to streamline your manufacturing processes, enhance productivity, and ensure operational excellence. Our comprehensive solution provides the tools needed to monitor, control, and optimize your manufacturing operations in real-time.

Our Key Features

Besfore Giving you the List of Detailed Features, Let us Show you some of our key features

Frequent Questions

EzeMES is a powerful manufacturing execution system that digitizes and integrates shop floor operations, offering enhanced visibility, Control, and Real-Time view. Integrating the Shop Floor with the Top Floor helps manufacturers leverage the full potential of the combined operations.

EzeMES is designed to seamlessly integrate with ERP systems, quality management systems, and other operational technology, enhancing data flow and process efficiency.

Yes, EzeMES is scalable and can be deployed across multiple facilities, providing a centralized view of all operations.

We offer 24/7 technical support, regular software updates, and comprehensive training sessions to ensure your team is fully equipped to use the system.

Any Questions? Let’s talk

Don’t Lose the Oppertunity to Get in Contact with Our Expert and Regret later

Advanced Production Scheduling

Ezemes empowers manufacturers by understanding the unique challenges of their production planning. Through advanced, finite capacity-based planning and scheduling, Ezemes provides accurate schedules and minimal downtime, ensuring businesses can operate efficiently. With our highly configurable logic, tailored to your specific operations and schedule changes, you can automate the scheduling process and work optimally.

Asset Management

IoT-enabled and Connected Machines elevate your manufacturing operations. Experience integrated operations, Machine insights, capacity, and availability for precise planning and execution. EzeMES’s business logic automates production scheduling based on machine availability and factors such as breakdowns and downtimes.

Shop Floor Data Capture

The operator’s app, written in vernacular for ease of operation, captures real-time operations data, including machine performance, production quantities, and quality metrics. EzeMES enables operator productivity with a prioritized backlog, on-screen work instructions, and a simple interface to log data without disrupting throughput.

Data Quality management

With EzeMES, quality control processes are digitized. Executing quality checklists, alerting for deviations, and providing detailed reports improves efficiency and accuracy in the process. Built-in templates include measurement and analysis metrics to target loss.

Maintainance Management

Plan and schedule your preventive maintenance with EzeMES. Create maintenance checklists and assign them to maintenance team. EzeMES promotes collaboration between Maintenance and Production teams. Operator app allows digital execution of maintenance checklists and schedules.

Advance Analytics

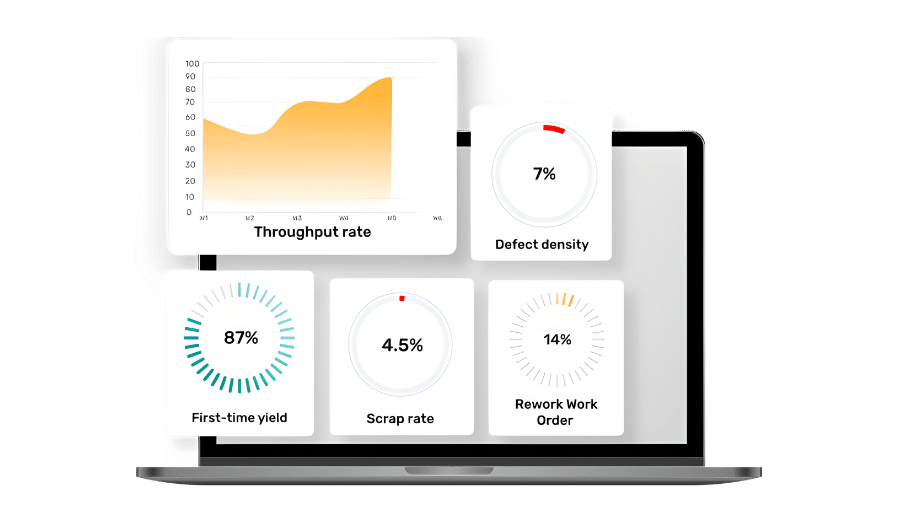

EzeMES offers function-specific dashboards, reports, KPIs, and metrics relevant to specific operational needs. These include intelligent insight and visibility that help increase efficiency, productivity, and profitability. Some out-of-the-box metrics include OEE, productivity, MTTR, MTBF, Quality and Production metrics, capacity and utilisation and more…

Any Questions? Let's Talk

Book a Free Demo today!

Jumpstart Smart Manufacturing

Konark Epitome, Viman Nagar, Pune 411014

© 2024 Plant Metrics Private Limited. All Rights Reserved. | Terms of Use | Privacy Policy